Steering Knuchles For Volkswagen Beetle -Z2490

The steering knuckle is one of the major parts of vehicle suspension and steering systems. It performs several essential functions, among them helping to guide the wheels. Learn about the steering knuckle in a car here where we examine its role, the materials used to make it and types, among other topics.

What is Steering Knuckle in a Car?

You must have heard about it, perhaps even had to replace in your vehicle, or sold it in your auto parts shop. But what is a steering knuckle and what does it do? Let’s begin by defining the component.

Steering Knuckle Definition

The automotive steering knuckle is the part that connects the steering to the wheels. It is usually a forged or cast assembly containing either a hub or spindle. On one end, the knuckle attaches to the wheel assembly and steering components on the other. It’s also sometimes called a spindle, hub, or upright.

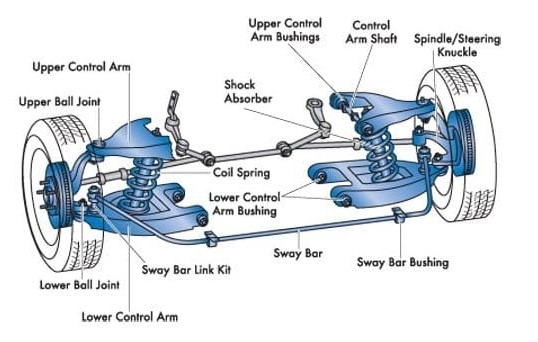

Here is a picture showing the steering knuckle

Steering knuckles come in many different sizes and designs, often to match the vehicle drive train, type of brakes, and suspension type or geometry. The knuckle of a MacPherson suspension is different from that of a frame suspension, for example.

Automotive steering knuckles are usually found at point where the steering meets suspension. To link the two systems, they come with arms and stud bores to mount relevant parts. The knuckles also feature a hub or spindle by which they attach to the wheels.

Among the parts of the suspension system that mount to the steering knuckle are ball joints, struts, and control arms. In vehicles that use disc brakes, steering knuckles also provide the surface to mount brake calipers.

Steering Knuckle Material

Many of the steering knuckles on the market today are made from forged steel. Cast iron has also been a popular material for these parts. Due to the emerging need for lighter vehicle parts, forged aluminum is fast becoming a major material for the knuckles.

Cast iron knuckles are less costly to make. The material also offers fewer challenges to machine. Despite these advantages, cast iron has some downsides. Casting produces blowholes that would subject a knuckle to damage, especially in heavy duty applications.

Forged steel makes knuckles that are strong, reliable, and long lasting. The material is difficult to machine, though. This makes the steering wheel manufacturing process when using steel costly, among other drawbacks.

Aluminum knuckles are lightweight and posses high ductility properties; just the right combination for inexpensive manufacturing, car fuel economy, and reduced emissions. A major disadvantage of aluminum is that it falls short when it comes to strength.

Steering Knuckle Function

The steering knuckle in a car is one of the most important parts. It holds the wheels in a plane, allowing them to turn in the motion of the steering wheel. By connecting the wheels and suspension to the steering linkages, the knuckles perform two essential roles: letting you steer the wheels while allowing their vertical motion.

The steering knuckle purpose can be summarized as:

To Support a Vehicle’s Weight

The knuckle supports the wheels, with pivoting connections to link it with the suspension. When the car is not moving, the knuckles hold the weight of the vehicle. When in motion, the components support part of the weight.

Help to Turn the wheels

Steering knuckles are the endpoints of the steering system components. They connect to the driver to the wheels, allowing the steering wheel inputs to convert to angular displacement of the wheels. As a result, you’re able to guide or control the car’s direction.

Mount the wheel

A steering wheel contains either a hub or spindle assembly. The spindle provides the mounting for wheel components such as bearings. The hub, on the other hand, allows the CV shaft that connects to (and drives) the wheels. That way, steering knuckles hold the wheels in place when the vehicle is both stationary and in motion.

Mount the Brake Caliper

Virtually every vehicle today uses disc brakes in the front wheels. Many have them in the rear axle, too. Disc brakes come with calipers that support and move the brake pads. To mount the calipers, steering knuckles come with bolt holes or bores.

For a knuckle to perform these functions, it has to be strong enough to stand up to different forces, mechanical wear, and corrosion. A lot of research goes into selecting the materials to use, designing the Knuckle structure, and finding the right finish for particular applications.

Application :

| Parameter | Content |

| Type | Shock absorber |

| OEM NO. | |

| Size | OEM standard |

| Material | ---Cast steel---Cast-aluminum---Cast copper---Ductile iron |

| Color | Black |

| Brand | For Volkswagen Beetle |

| Warranty | 3years/50,000km |

| Certificate | ISO16949/IATF16949 |